Aluminum tile trim, Model No.: X-002, Closed type, Width: 36mm, Height: 14.16mm.

High-quality aluminum alloy raw materials are selected, clear and good texture;

Formed by hot extrusion technology through our company's existing product molds;

Aging treatment enhances strength and hardness, no deformation, good impact resistance;

After the surface is pre-treated, it is anodized and colored, no fading, no rust;

Waterproof, moisture-proof, strong corrosion resistance;

Wide applicability, multi-color optional, suitable for decoration of different styles;

Environmental protection is safer, no odor, no formaldehyde, no radiation.

Anodizing: It can form a uniform and dense oxide layer on the surface of the product, and this film can make the surface hardness of the product reach (200-300HV). Anodizing can color the product, and the product has good decorative and wear resistance. Anodizing has strict requirements on materials, and different materials have different decorative effects on the surface. Commonly used materials are 6061, 6063, 7075, 2024, etc. Among them, 2024 is relatively less effective. Due to the different content of CU in the material, 7075 hard anodized is yellow, 6061, 6063 is brown, but ordinary anodized 6061, 6063, 7075 is not much different, but 2024 is prone to many gold spots.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

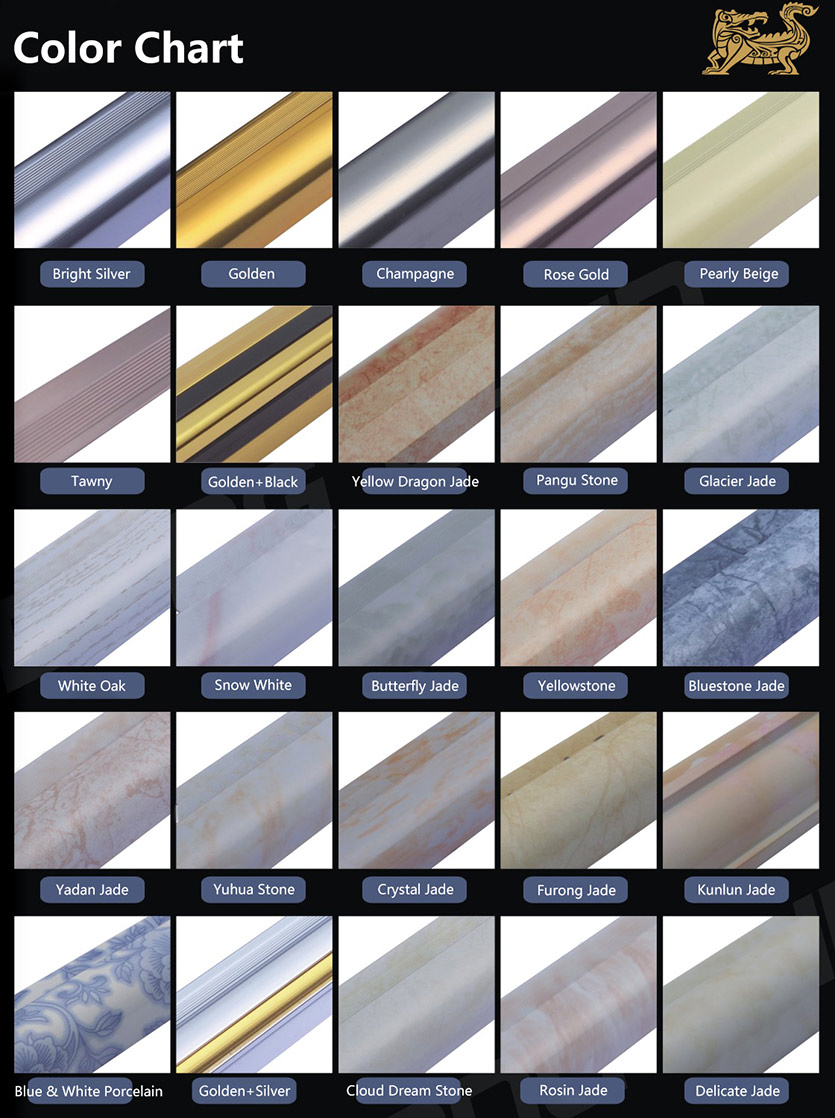

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

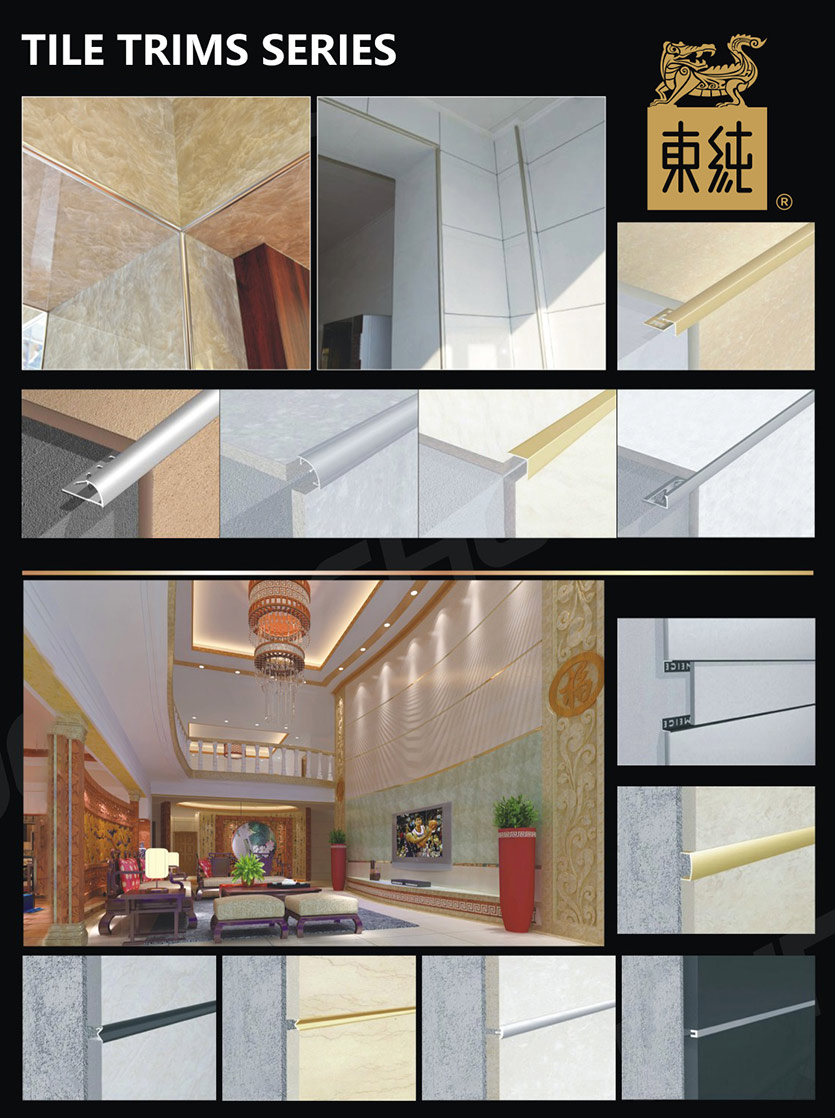

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Open Type 069B Anodized Poli...

-

Aluminum Tile Trim F Shape J03B Spray Coating &...

-

Aluminum Tile Trim Closed Type X-002 Spray Coat...

-

Aluminum Tile Trim Right Angle L Shape 25×...

-

Aluminum Tile Trim Closed type Multiple Models ...

-

Aluminum Tile Trim E Shape 25X21 Anodized Brigh...