Aluminum tile trim, Model No.: XHL-02B, Closed type, Width: 37mm, Height: 13mm.

The product is formed by hot extrusion of high-quality aluminum alloy raw materials. After the aging treatment process is used to strengthen the hardness of the product, the surface of the product is treated and colored by anodizing technology.

Process characteristics

1. Porosity - The oxide film has a porous honeycomb structure, which can make the film layer show good adsorption capacity for dyes and paints, dye the oxide film into various colors, and improve the decorative effect of the metal.

2. Wear resistance - The aluminum oxide film has high hardness, which can improve the wear resistance of the metal surface.

3. Corrosion resistance - aluminum oxide film is very stable in the atmosphere, so it has good corrosion resistance. In order to improve the corrosion resistance of the film, the film layer after anodization is usually sealed or painted.

4. Electrical insulation - the anodic oxide film has high insulation resistance and breakdown voltage, and can be used as the dielectric layer of electrolytic capacitors or the insulating layer of electrical products.

5. Thermal insulation - aluminum oxide film is a good thermal insulation layer, and its stability can reach 1500 ℃.

6. Bonding force - The bonding force between the anodized film and the base metal is very strong, and it is difficult to separate them mechanically. Even if the film is bent with the base until it breaks, the film and the base metal still maintain a good bond.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

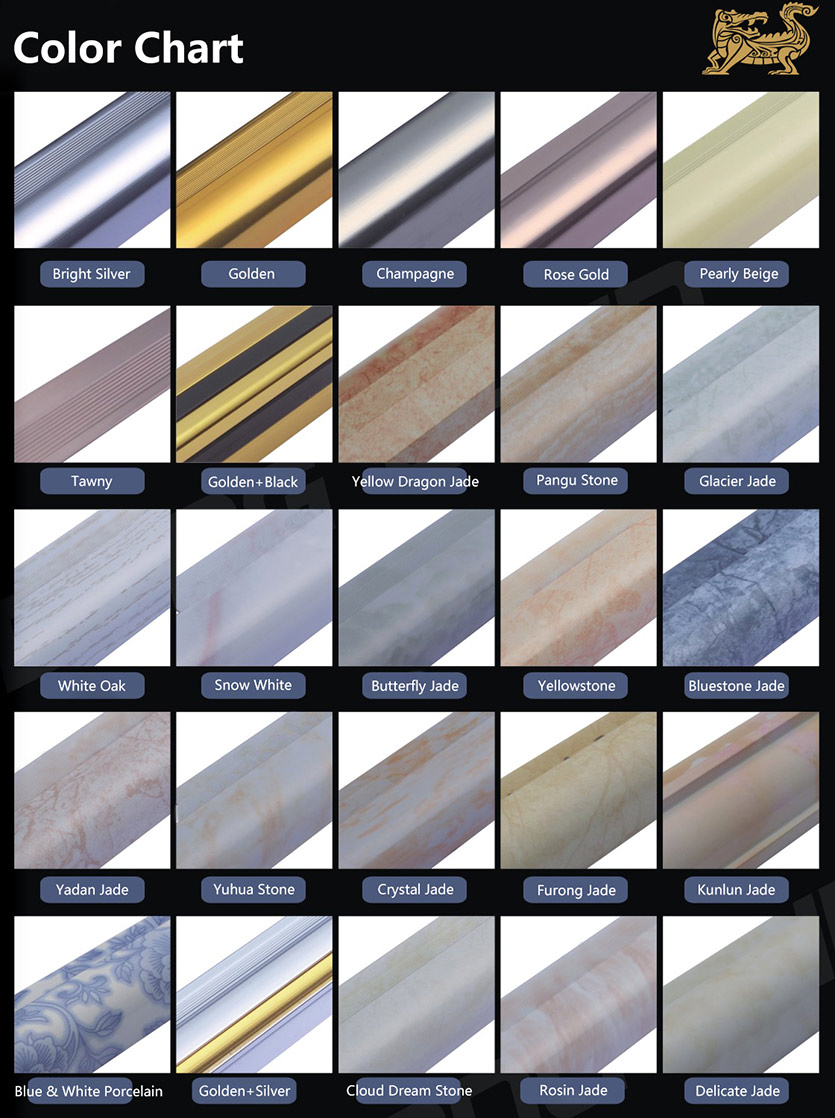

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

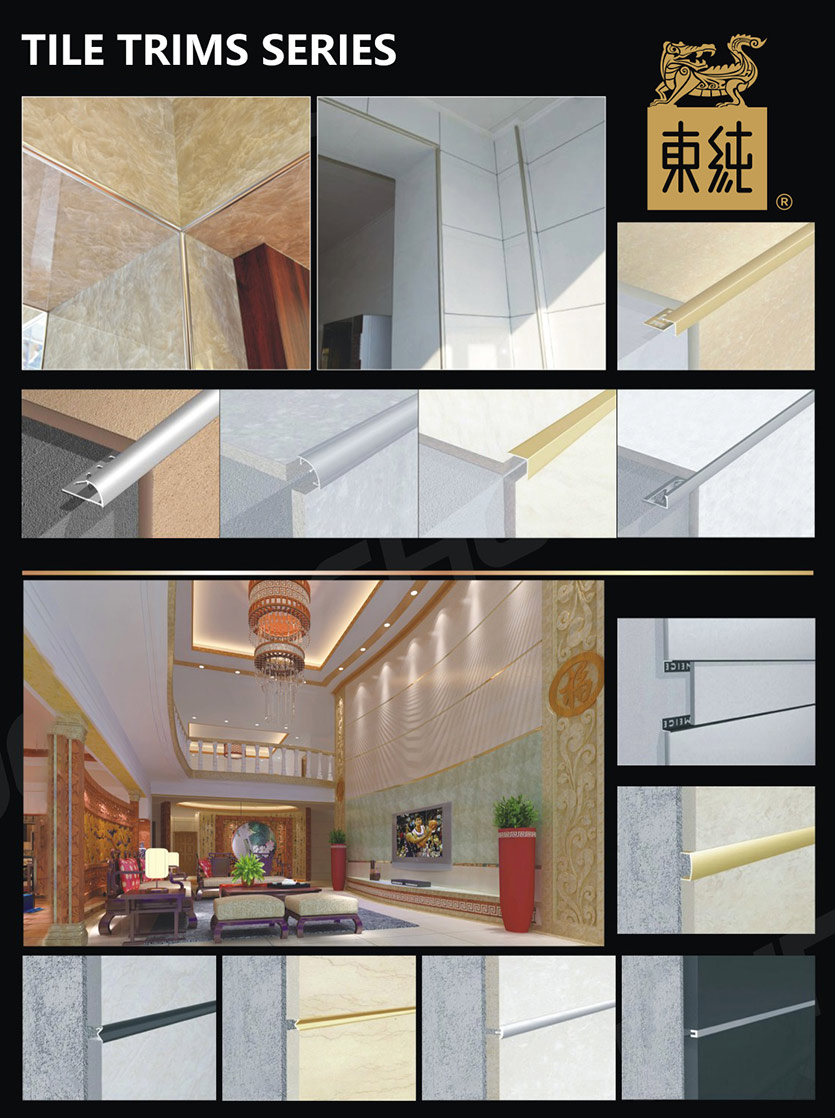

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim L Shape 019D Thermal Transfe...

-

Aluminum Tile Trim Open Type X10 Spray Coating ...

-

Aluminum Tile Trim L Shape 019D Anodized Champagne

-

Aluminum Tile Trim F Shape J03B Anodized Bright...

-

Aluminum Tile Trim Open Type X10 Anodized Matte...

-

Aluminum Tile Trim F Shape 028C Spray Coating &...