Aluminum tile trim, Model No.: 15x15, L shape, Width: 15mm, Height: 15mm.

This product is made of high-quality aluminum alloy material, which is formed by hot extrusion technology, and the strength and hardness of the material are improved by aging treatment technology, and then colored by anodizing process.

The anodizing of aluminum is an electrolytic oxidation process. During this process, the surface of aluminum and aluminum alloys is usually transformed into an oxide film that has protective, decorative, and other functional properties. The anodization of aluminum from this definition only includes the part of the process of forming an anodized film.

A metal or alloy product is used as an anode, and an oxide film is formed on the surface by electrolysis. Metal oxide films change the surface state and properties, such as surface coloration, improve corrosion resistance, enhance wear resistance and hardness, and protect metal surfaces.

Choose more models

Please look for your required styles from our designs, or send your CAD drawing for goods customization.

Aluminum Tile Trims SPEC

| Goods Raw Material | Aluminium alloy (6063-T5) |

| Goods Details | Length: 3 meters, 2.7 meters, 2.5 meters. |

| Thickness: 0.4 millimeters to 2 millimeters. | |

| Height: 8 millimeters to 25 millimeters. | |

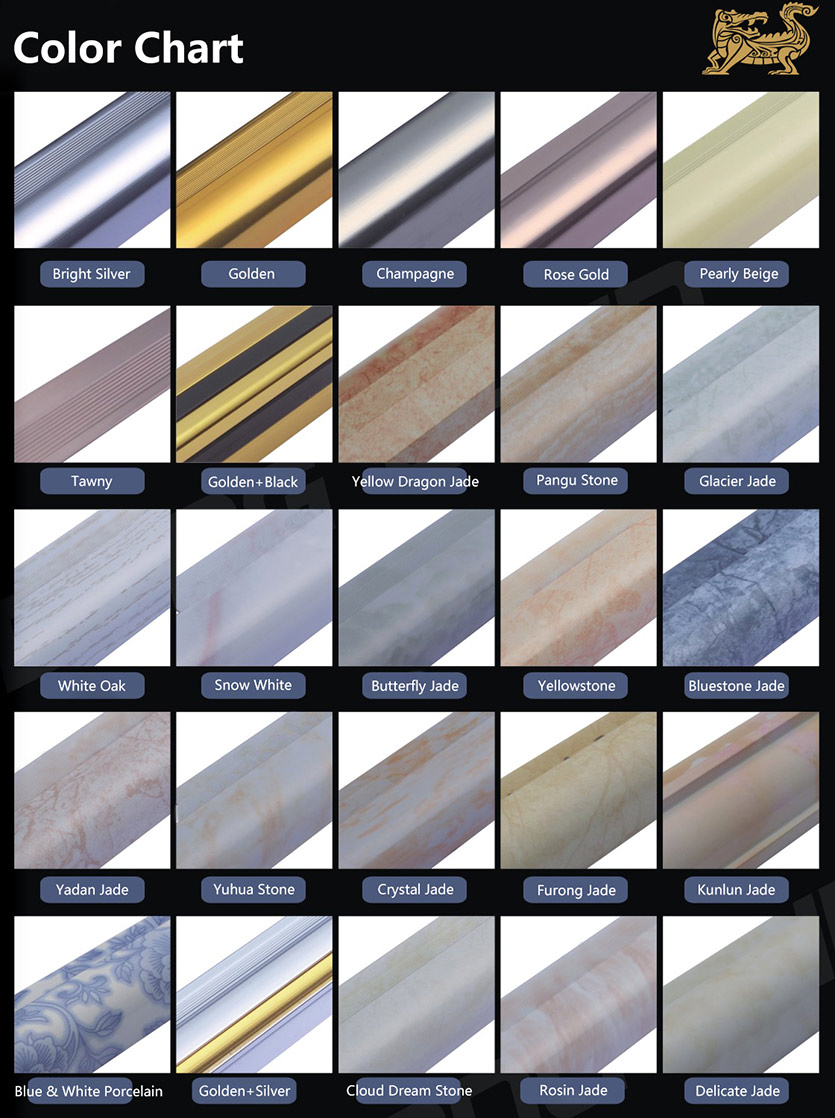

| Color: Brown, Champagne, Black, Yellow, Silver, Gold, Copper, White, Grey, etc. | |

| Shapes: L/E/F/U/T shape, Open Type, Closed Type and others. | |

| Goods Surface Finish | Spray coating, Anodizing, Polishing, Thermal transfer printing, etc. |

| Goods Punching Hole | Letters of logo, Square, Round, Rhombic, Triangle. |

| Purpose Of Use | For the edges decoration and edges protection of marbles, glass, tiles, UV panels, etc. |

| OEM and ODM | Welcome |

Since entering the industry, our company has accumulated 16 years of production experience, and has brought together many technical and management talents with rich industry experience. During production, our team strictly controls the manufacture of products in accordance with quality management, to ensure product quality, to ensure production capacity and to ensure on-time delivery. If customers have special customization requirements, we can also provide drawing design and mold making services.

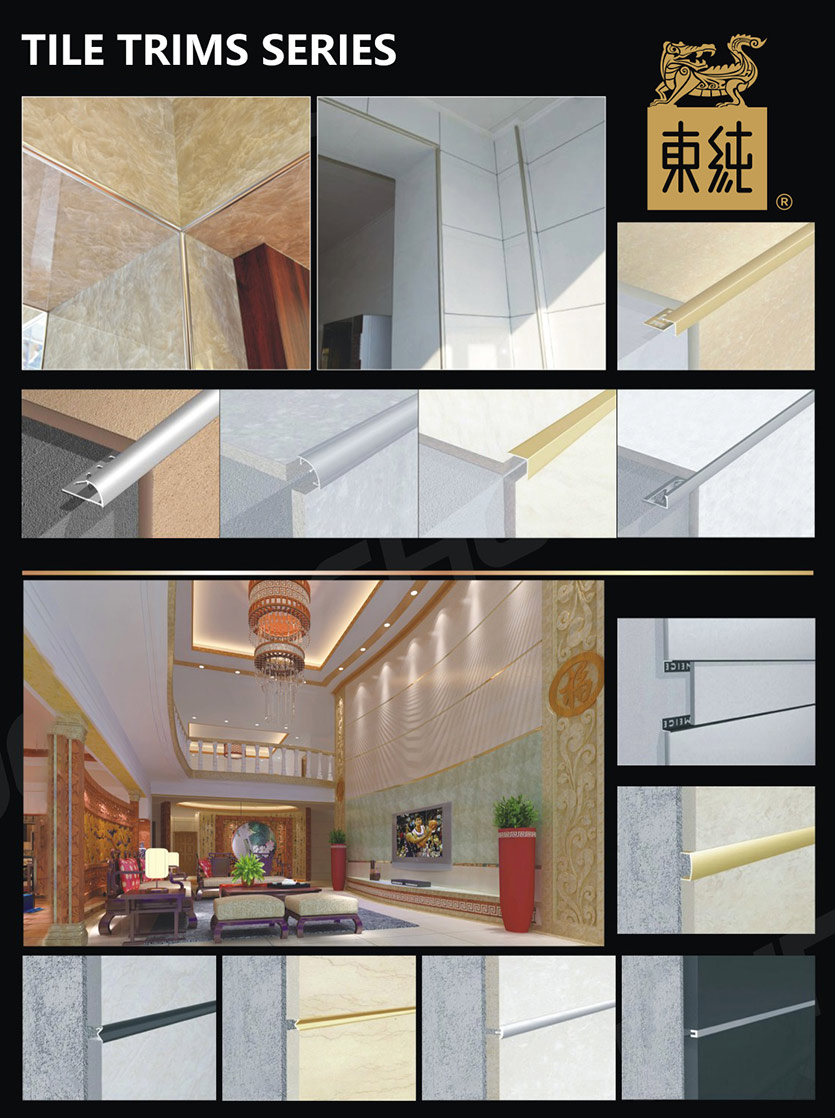

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Open Type X10 Anodized Matte...

-

Aluminum Tile Trim Closed Type XHL-02B Spray Co...

-

Aluminum Tile Trim F Shape 028C Anodized Polish...

-

Aluminum Tile Trim Closed Type XHL-02B Anodized...

-

Aluminum Tile Trim Open Type 069B Spray Coating...

-

Aluminum Tile Trim U Shape M30 Spray Coating &#...