Many styles of aluminum tile trim, Model No.: 12B701/12B5/X6, Open type/Closed type, Please refer to CAD drawing for width and height.

Good quality aluminum alloy raw materials are used for these products, after hot extrusion molding, through aging treatment technology to improve the strength and hardness, and then to spray required color and thermal transfer pattern on the surfaces.

The tile trim can not only protect the corners of the tiles, but also decorate and cover the gaps. It is a kind of decorative line that protects the corners of the tiles. One side is sheet-shaped, inserted into the wall during construction, and the exposed fan-shaped side wraps the outer corner of the tile. The colors are golden yellow, rose gold, silver gray, stainless steel mirror color, etc. The materials are generally plastic, aluminum alloy, stainless steel, and PVC.

The traditional tiling angle is generally a right angle. Families with children can choose thick tiles and tile trims with inverted arcs to solve potential safety hazards. In terms of materials, it is generally used to choose aluminum alloy material or PVC material.

In addition to protecting the corners of the tiles, the tile trims can also beautify and cover up the defects of the tiles. For example, some tiles have irregular cross-sections, and it is difficult to make a perfect seam at the joints of the outside corners, and the tile trims can cover them up.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

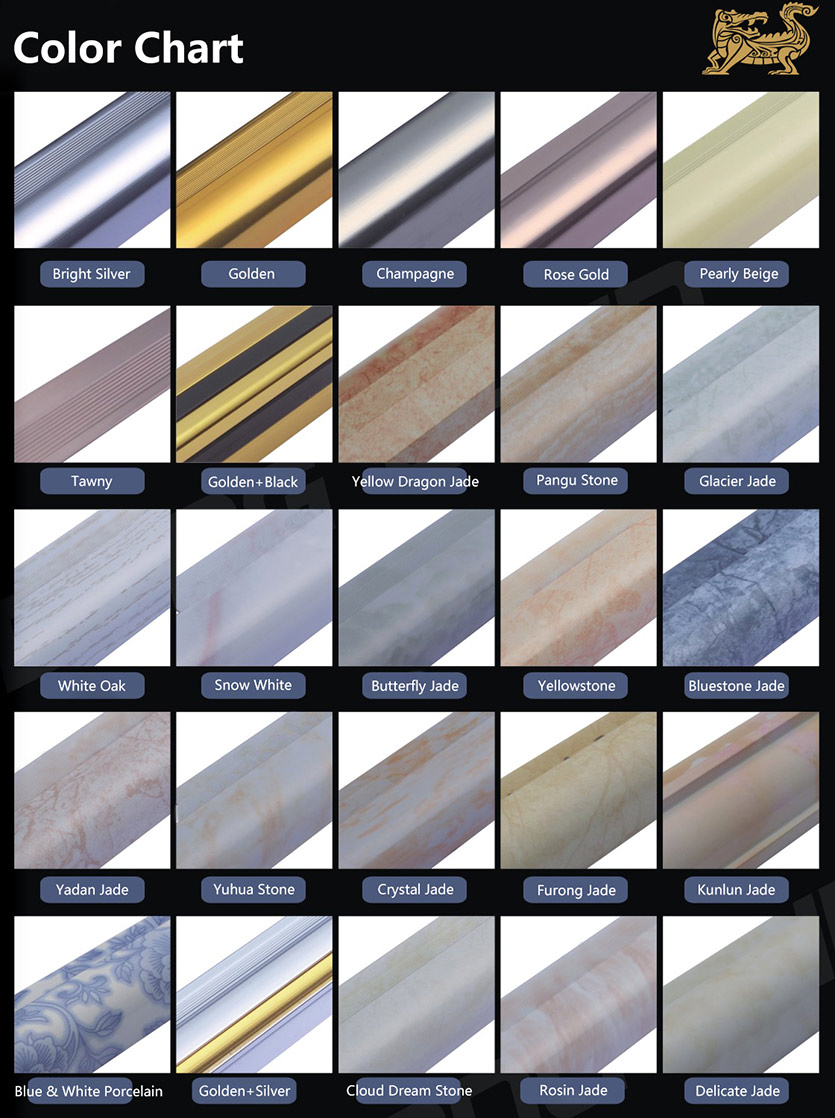

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

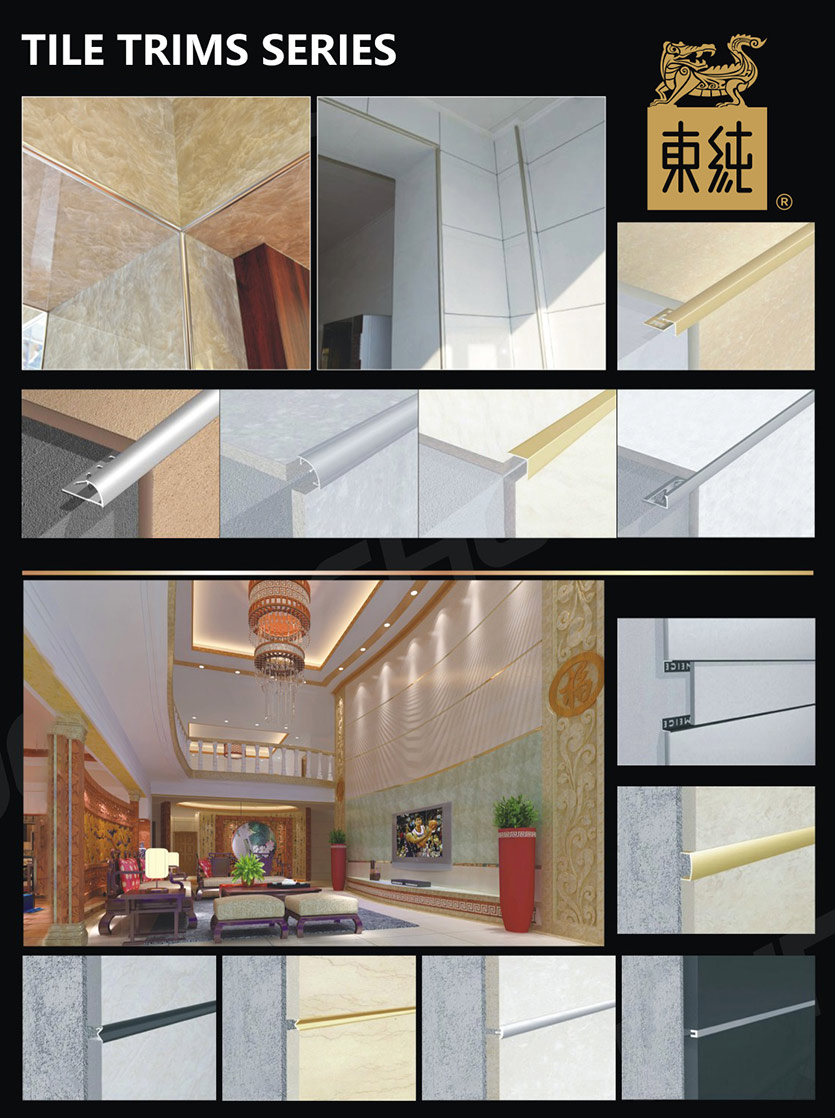

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Closed Type XHL-02B Spray Co...

-

Aluminum Tile Trim L Shape 15×15 Anodized ...

-

Aluminum Tile Trim Closed Type X-002 Anodized B...

-

Aluminum Tile Trim F Shape 028C Spray Coating &...

-

Aluminum Tile Trim E Shape 25X21 Anodized Brigh...

-

Aluminum Tile Trim Open Type X10 Spray Coating ...