Multiple styles of aluminum tile trim, Model No.: C10-180/G92/G43/M29/21x20, Other type, Please refer to CAD drawing for width and height.

Products are made of high quality aluminum alloy raw materials by using hot extrusion molding technology. The strength and hardness are improved through aging treatment technology, and then to spray bottom color and thermal transfer patterns on the surfaces according to customers’ demands.

In modern decoration, when the wall is tiled, the traditional way of cutting the corner of the tile and then docking it is used to deal with the corner of the wall, which is difficult, and the docking corner is sharp and unsafe. Therefore, most people take the method of wrapping and protecting with tile trim. On the one hand, it can improve the efficiency of construction, and on the other hand, it can decorate the walls, which directly affects the overall effect of the decoration and reflects the level of the overall decoration.

What are the advantages of tile trim in decoration?

1. To achieve the harmonious and unified effect of house space, plane and line;

2. During the decoration and construction, the trouble caused by cutting and grinding the edge of the tile can be avoided, thereby reducing the waste of materials and protecting the environment;

3. The construction operation is convenient, which can save labor and time;

4. The tile trim not only has the effect of beautifying the decoration, but also can play the role of safety protection;

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

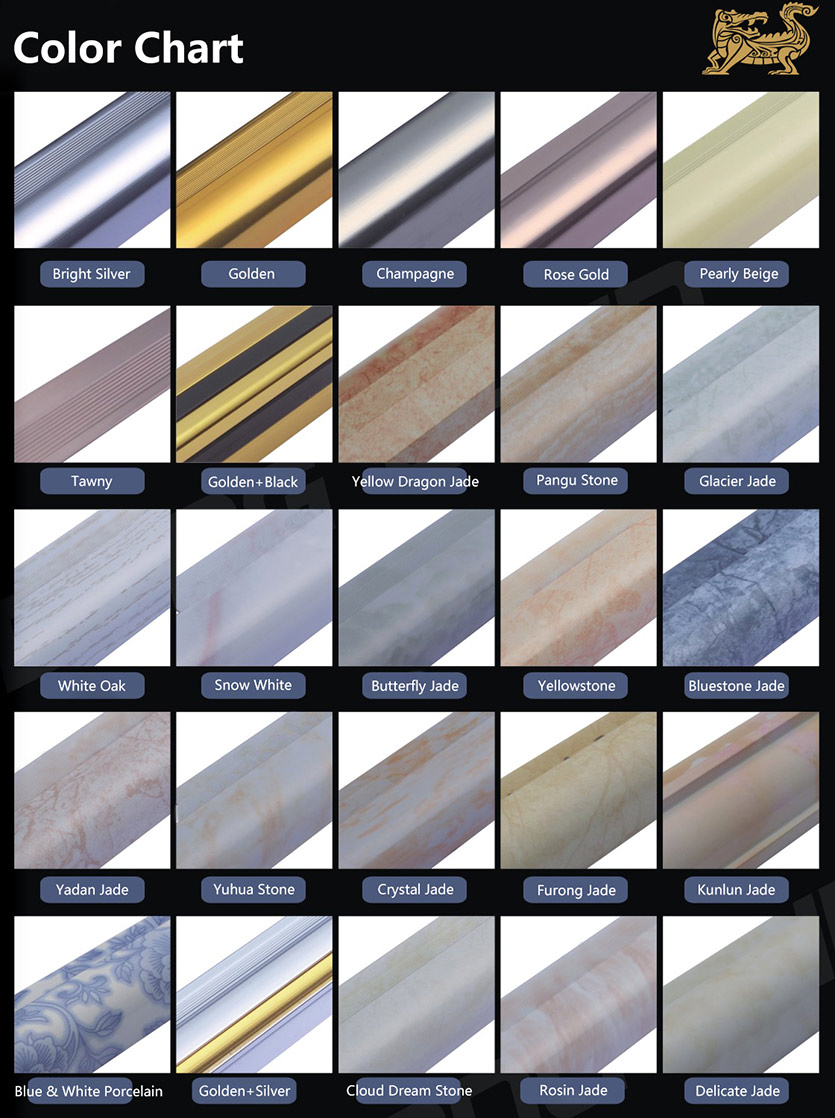

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company supports OEM/ODM service, can carry out one-stop service production, and can also carry out processing needs of individual links, such as: hot extrusion needs, aging treatment needs, profile cutting needs, punching needs, anodizing needs, spraying needs, lamination packaging needs, etc.

Warmly welcome customers to choose our existing styles, and welcome to customize with drawings and samples.

Our advanced equipment, perfect production management system, and professional technicians can meet your various customized needs, so that your orders can be produced without worry and delivered in time.

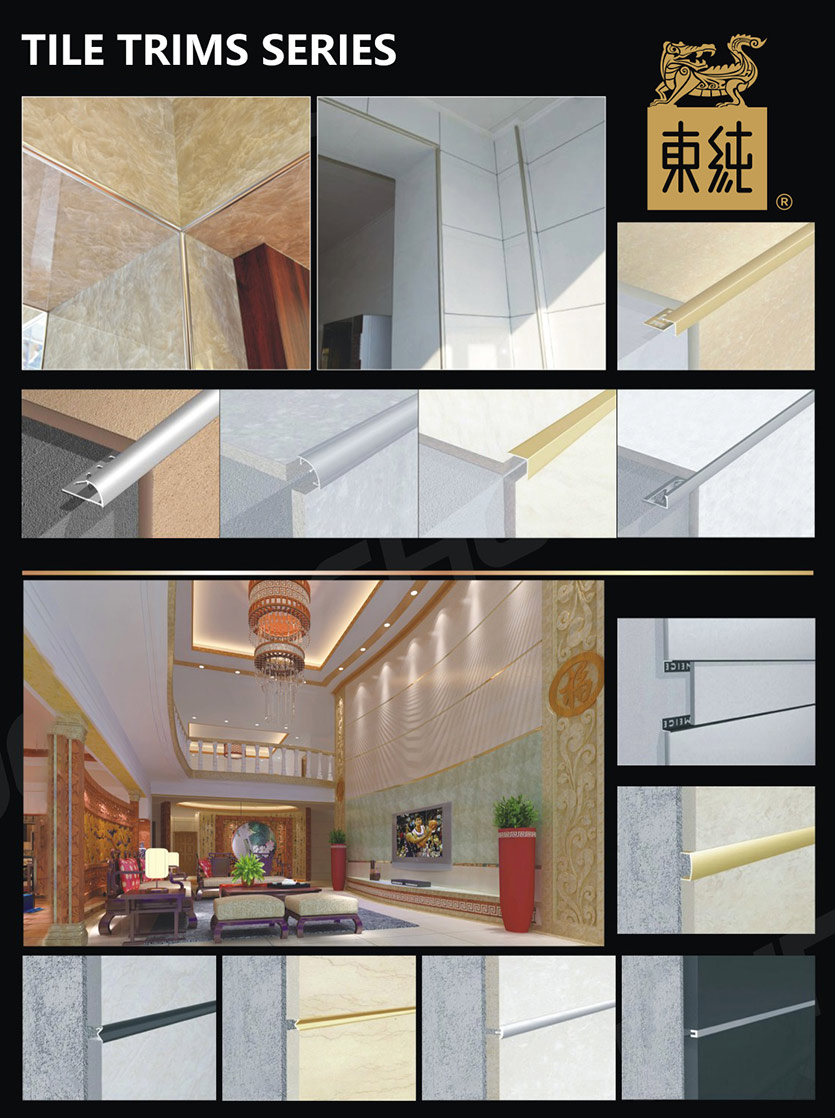

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Open Type 12C8 Thermal Trans...

-

Aluminum Tile Trim Open Type X9 Spray Coating &...

-

Aluminum Tile Trim Closed Type XHL-02B Anodized...

-

Aluminum Tile Trim Closed Type X-002 Anodized B...

-

Aluminum Tile Trim Closed Type X-002 Spray Coat...

-

Aluminum Tile Trim L Shape 019D Anodized Champagne