Aluminum tile trim, Model No.: 069B, Open type, Width: 31.8mm, Height: 12.5mm + 2.5mm.

Select high-quality aluminum alloy raw materials, after hot extrusion molding and aging treatment, spray the bottom color on the surface and then thermal transfer pattern.

Instructions:

1. Clean up the working surface, remove the bulge, and fill up the depression.

2. Make mixed grout, smooth the corners and walls with the mixed grout, and keep the grout to an appropriate thickness.

3. Close the tile trim to the corner of the wall (it is advisable if there is slurry overflowing from the punching hole, it is recommended to use caulking paste or nails to fix it). When the length of the tile trim is not enough, it can be spliced, and keeping the same straight line;

4. Tile fitted to both sides of the tile trim.

Discover more from CAD DRAWING

Send us your CAD file to customize, or look for your required products from our own styles.

Particulars Of Aluminum Tile Trims

| Aluminium alloy | 6063(T5) |

| More info | 1.Length available: 3m, 2.7m, 2.5m |

| 2.Thickness available: 0.4mm to 2mm | |

| 3.Height available: 8mm to 25mm | |

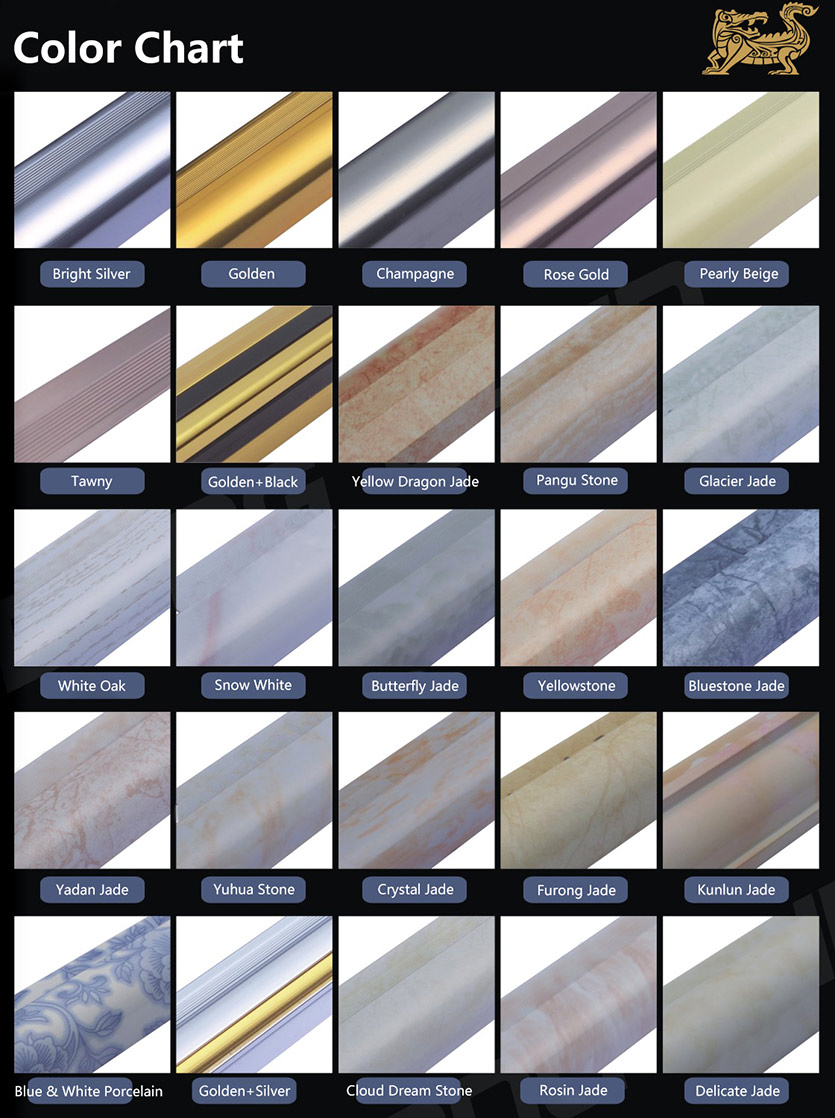

| 4.Color available: White, Silver, Black, Gold, Grey, Champagne, and so on. | |

| 5.Shapes available: L shape, E shape, F shape, U shape, T shape, Closed Type, Open Type and others. | |

| Finishing | Anodizing, Polishing, Thermal transfer printing, Spray coating, etc. |

| Punched Holes | Triangle, Rhombic, Logo letters, Round, Square. |

| Be used to | Decorate and Protect the edges of tiles, marbles, UV panels, glass, etc. |

| OEM/ODM | Both are available. |

Our company can provide one-stop service, including drawing design, mold making, machining (such as heat treatment, profile cutting, punching, etc.), finishing (such as anodizing, painting, etc.), packaging, etc. Our technical team and production team have rich industry experience and production experience. All links from raw material procurement to production are strictly controlled in accordance with international standards to ensure product quality and on-time delivery.

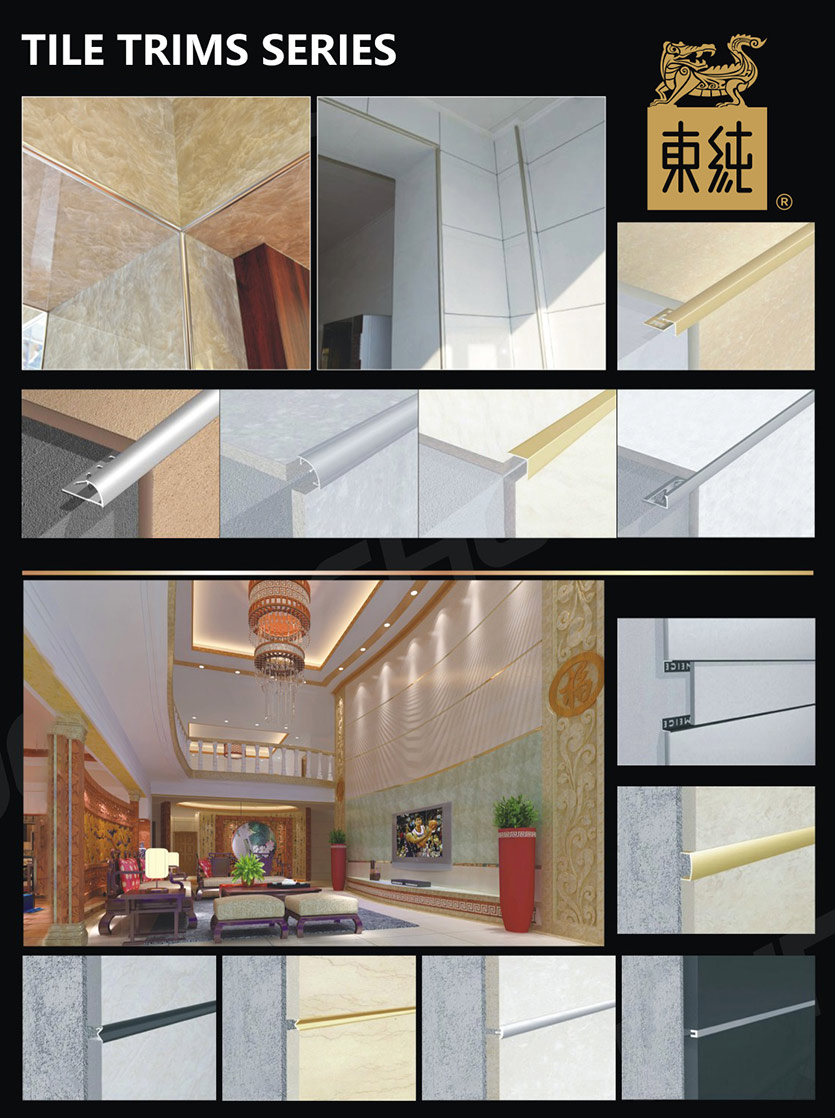

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Open Type X10 Anodized Matte...

-

Aluminum Tile Trim L Shape 25X25 Anodized Polis...

-

Aluminum Tile Trim Anodized Multiple Models K13...

-

Aluminum Tile Trim Closed Type X-002 Anodized B...

-

Aluminum Tile Trim F Shape 028C Anodized Polish...

-

Aluminum Tile Trim Right Angle L Shape 25×...