Aluminum tile trim, Model No.: J04B, Open type, Width: 35.8mm, Height: 12.8mm + 3.84mm.

Hot extrusion molding with high-quality aluminum alloy raw materials, improve hardness and strength by aging treatment, spray background color on the surface and thermal transfer printing with different patterns.

Advantages of using tile trim:

1. Easy to install, save labor, time and material. When using tile trims, the tiles or stones do not need to be ground and chamfered, and workers who can paste tiles and stones only need three nails to complete the installation.

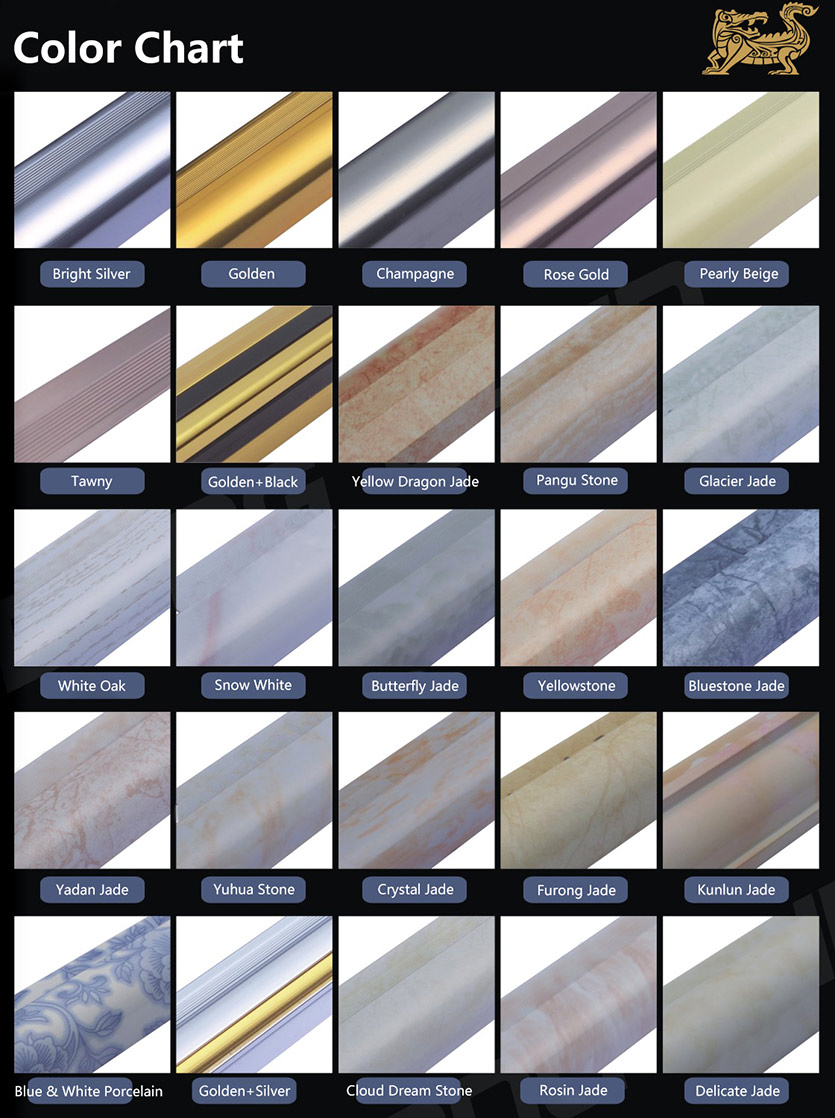

2. Beautiful and bright decoration. The curved surface of the tile trim is smooth and the line is straight, which can effectively ensure the straightness of the corner of the wrapping edge and make the corner of the decoration more three-dimensional.

3. The colors are rich and can be matched with the same color to achieve the consistency of the tile surface and the edge line, and can also be matched with different colors to form a contrast.

4. It can well protect the corners of tiles.

5. The product has good environmental protection performance, and the various raw materials used have no adverse effect on the human body and the environment.

6. Safety, the arc eases the right angle to reduce the harm caused by the collision.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

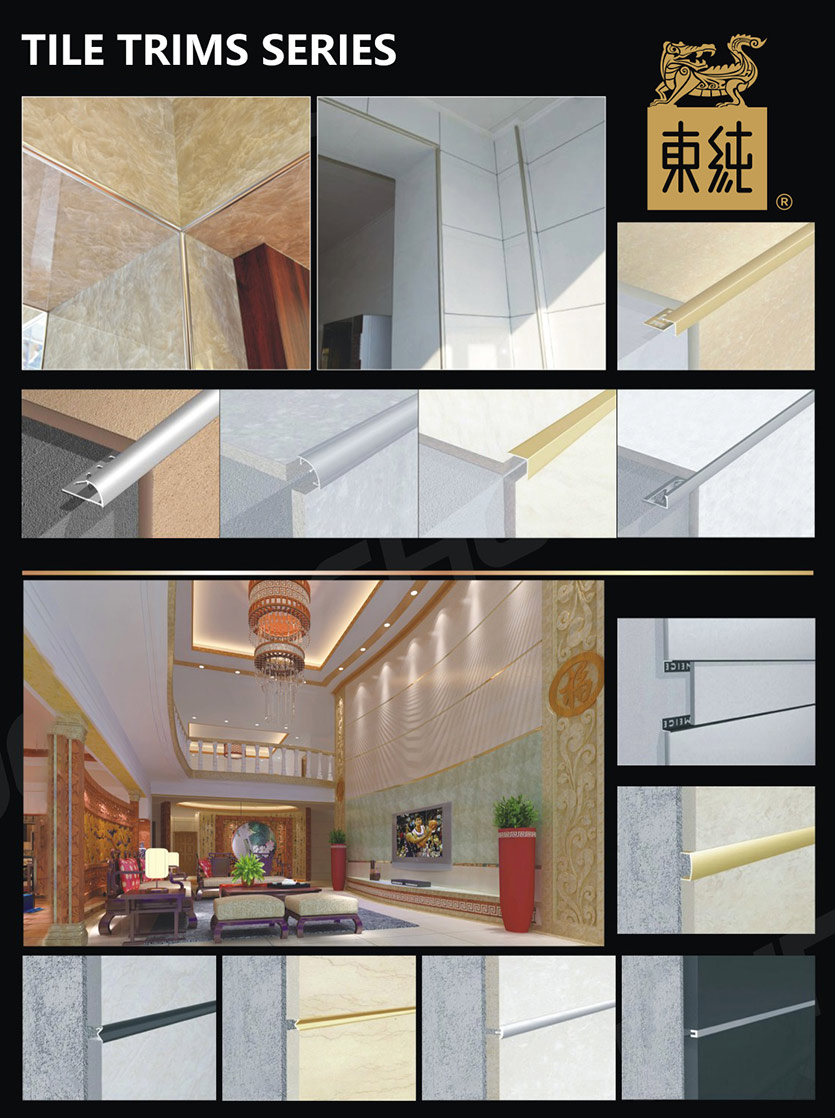

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Aluminum Tile Trim Open Type X9 Anodized Polish...

-

Aluminum Tile Trim Open Type X10 Spray Coating ...

-

Aluminum Tile Trim Many Styles 12B701/12B5/X6

-

Aluminum Tile Trim L Shape 019D Thermal Transfe...

-

Aluminum Tile Trim F Shape 028C Spray Coating &...

-

Aluminum Tile Trim L Shape 019D Anodized Champagne