PVC tile trim, Model No.: DC15, Two edges, Width: 20.5mm, Height: 15.5mm+2.5mm.

Special structure to meet special decoration needs.

The product is made of environmentally friendly PVC material, without formaldehyde.

The surface is treated by thermal transfer printing process, which is realistic and beautiful.

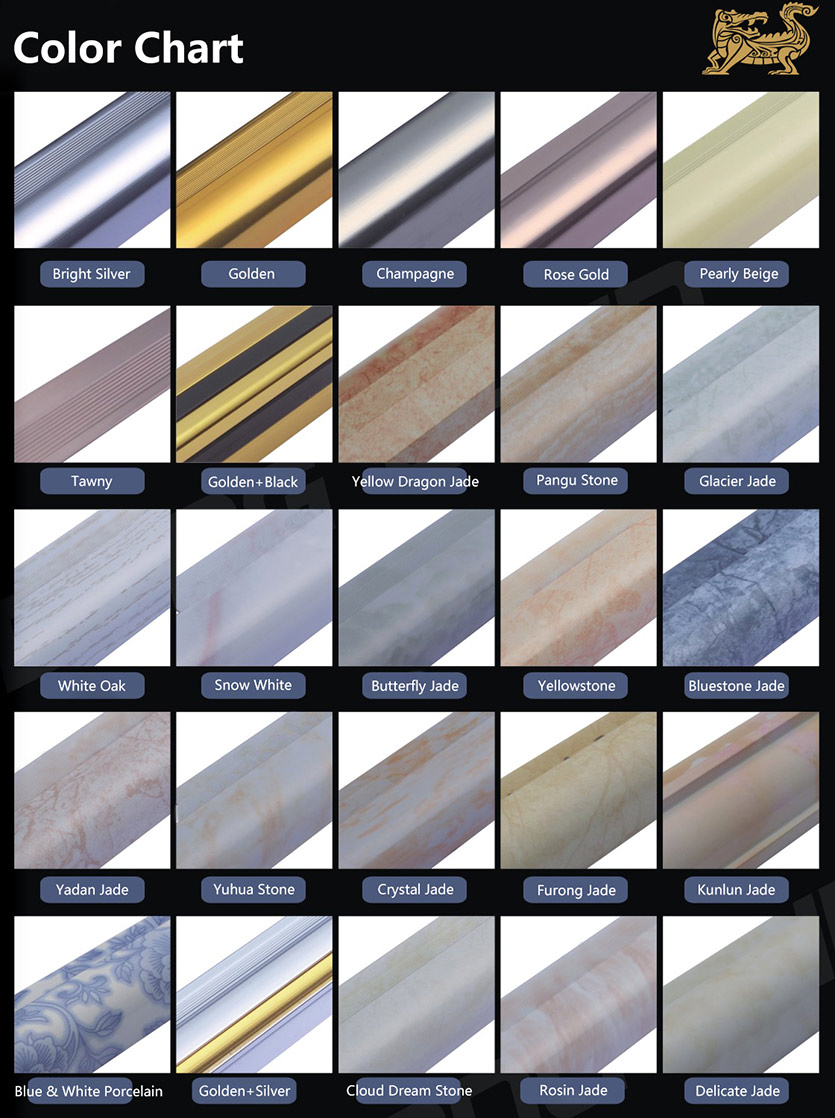

Length, color, pattern, etc. can be customized.

Why use tile trim?

1. The corner is a place where it is easy to be bumped, especially frequent walking or handling will damage the corner, causing life-long damage to the corner.

2. Children often run around, and the tile trim plays a protective role.

3. The choice of tile trim is an inevitable product of post-decoration, which solves the problem of easy damage to wallpaper decoration, and allows protection and art to have at the same time.

4. Tile trim can add a family atmosphere, versatile corner guards, soft colors, and simple lines can relieve the load in our hearts, give us a sense of relaxation and pleasure, and awaken our desire to go home.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About PVC Tile Trims

| Material | PVC |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Open/Solid/Edgeless/Triangel hole/Two edges/Semicircle/Large semicircle/Right angle/F buckle/Airplane shape | |

| Surface Treatment | Thermal transfer printing |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

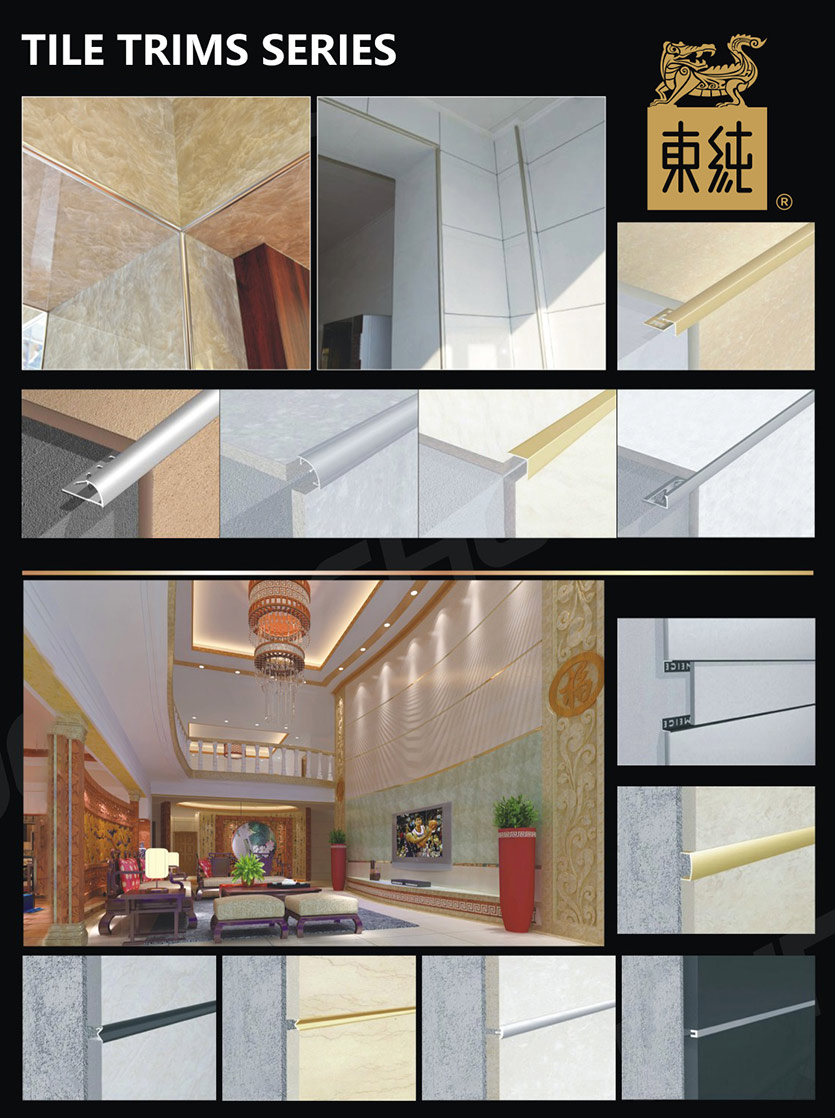

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners

-

Tile Grout OEM Custom Various Colors Available

-

Aluminum Tile Trim E Shape 25X21 Anodized Brigh...

-

Aluminum Tile Trim Closed Type X-002 Spray Coat...

-

PVC Tile Trim DC03 Airplane Shape Thermal Trans...

-

Aluminum Tile Trim L Shape 019D Anodized Champagne

-

Aluminum Tile Trim Anodized Dark Brown Multiple...